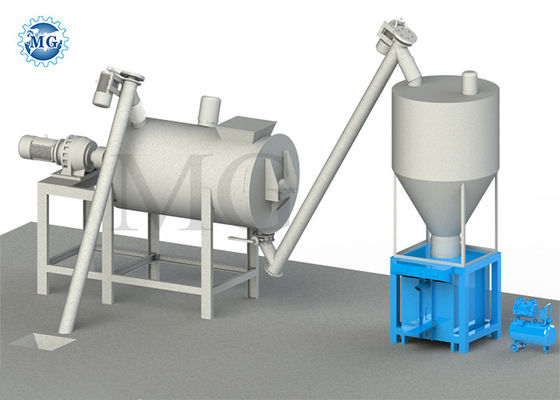

1.Description of Dry Mix Mortar Tile Adhesive Manufacturing Plant.

MG series Dry Mix Mortar Tile Adhesive Production Line Manufacturing Plant is designed according to the traditional single mixer machine, and adding material transportation system, finished product storage silo and automatic packing machine, and forms one whole simple dry mortar production line, improves the working efficiency a lot, it can finish the work from feeding, mixing, conveying to packing automatically.

2.Product Configuration of Dry Mix Mortar Tile Adhesive Manufacturing Plant.

| Model |

Capacity |

Occupied area |

Equipment height |

Manpower |

Batching and packaging |

| Simple type |

3-4t/h |

20㎡ |

3-4m |

2-3 Person |

Manual batching

Automatic packaging |

| Semi-automatic type |

6-8t/h |

50-60㎡ |

6-8m |

3-4 Person |

Manual batching

Automatic packaging |

| Full automatic type |

8-30t/h |

60-100㎡ |

8-13m |

3-4 Person |

Automatic batching

Automatic packaging

|

1. Ribbon Mixer Machine.

The screw ribbon mixer is the most high economy and cost-effective dry mortar mixer,the outer and inner screw ribbon blade driven by high speed rotating shaft, mixing the material in maximum, inner screw ribbon blade forced the material to sides ,outer screw ribbon blade forced sides material to inward, mix the materials back and forth. so to achieve uniform mixing effect in relatively short time.this is its working principle,the mixing time is about 10-15min/batch.

Model: 165*3500, 219*3500

Material: Q235A

Thickness: 3mm

Diaimeter: Φ165mm, 219mm,etc

The screw conveyor is Φ165X3500mm, the mixer mortar is transferred from mixer to finish product hopper.

Motor: 5kw, 7.5kw, 11kw, etc

Model: 0.9m3, 1.8m3, 2.8m3

Material: Q235A

Capacity: 0.5 T/batch, 1 T/batch, 2 T/batch

3 T/batch

Mixing Speed: 10-15 min/batch

3. Finished Product Storage Silo.

The finished product hopper is about 1.5m³, to store the finished material and prepare for the packing machine, which improves the efficiency a lot.

Volume:1.5m³, 2.5m³, 3.7m³

Diameter:Φ1250mm

Thickness: 3mm

Material: Q235A

4. Automatic Packing Machine.

Automatic dry mortar packing machine,valve type, 15-50kg/bag adjustable, 4kw, the packing speed is about 5-6s/bag. High packing speed, high weighing accuracy, high degree of automation, simple operation,and easy maintance.

Packing Accuracy:>98%

Weighing Range:15-50 kg/bags

Packing Speed:4-6s/bag

Air Pressure Demend:0.4 Mpa

Bag Materials:Valve type paper/PP/Plastic

0.25m³, 2.2kw, providing air source for automatic packing machine and finished product hopper,achieving quick packing and broken arch of finish product hopper.

3. Working Principle of Dry Mix Mortar Tile Adhesive Manufacturing Plant.

Firstly, the raw material is put into the feeding pot of screw conveyor, then transported into the mixer by screw conveyor,secondly, several kinds of raw material will be mixed by the multi ribbon screw mixer, thirdly,the mixed material will be transported into the end product silo by second screw conveyor, fourthly, the finished product will be packed into bags by packing machine.

4. Raw Materials of Dry Mix Mortar Tile Adhesive Manufacturing Plant.

5. Application of Dry Mix Mortar Tile Adhesive Manufacturing Plant.

6. FAQ

1. How is the quality of your products?

Our machines are manufactured strictly according to national and international standards, and we will assemble and test all the equipment and pack them carefully before delivery. We have exported to lots of countries around the world, such as Australia, Malaysia, India, Indonesia, Vietnam, etc. You can rest assured with the quality absolutely.

2. What is your business model? Trading company or factory?

We are a factory with our own mechanical design engineers and project design engineers, all our machinery are manufactured by ourselves.

We can provide customized solution design according to customer needs, and full-process services such as early project communication, scheme design, equipment selection, equipment production, site planning, equipment layout, transportation and delivery, installation and commissioning.

3. Do you provide after-sale service?

Yes. The warranty period of our machines is 12 months, and we have a professional after-sale service team to promptly and thoroughly solve your problems.

4. Do you provide equipment operation training?

Yes. All of our engineers have passports. We can send experienced engineers to the customer's site to guide equipment installation, debug the production line until it is put into production, we will also provide installation instructions, layout drawings, assembly drawings, etc. If the customer has his own engineer, he can install the equipment according to the installation steps drawings we provide, and we can also guide the installation with online videos.

5. Can I visit your factory?

Yes! Welcome to visit our factory, many domestic and international customers visit our factory every year. We can provide you the invitation letter required for visa application. We will meet you at the airport or station and provide professional business reception services.

6. What is the process for purchasing equipment?

Contact customer service —understand the basic situation — equipment quotation — sign contact — equipment production

If you are interested to our dry mortar production line, please feel free to send us inquiry or leave your contact number for us.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!